Top Hanger Bolt Factory in China: Leading Manufacturer for Quality Fasteners

2026-01-06

Welcome to our in-depth look at the leading hanger bolt factory in China, where quality and precision are paramount in the fastener industry. As a key player, this manufacturer sets the standard with innovative solutions that meet global demands. At Topfence, we celebrate such excellence, offering insights into how top-tier products can elevate your projects. Discover more about their cutting-edge processes and why they're the go-to choice for reliable fastening solutions—stay tuned for an exclusive exploration.

Discover the Excellence of Our Hanger Bolt Production in China

When it comes to hanger bolt production, our facilities in China set the standard for quality and precision. We leverage state-of-the-art CNC machinery and rigorous quality control processes to ensure every bolt meets exact specifications, from thread consistency to material strength. Our commitment to excellence means we can handle custom orders with ease, providing durable solutions for furniture, construction, and industrial applications worldwide.

What truly distinguishes our production is our focus on innovation and sustainability. We source high-grade steel and eco-friendly coatings to enhance corrosion resistance while reducing environmental impact. Our team continuously refines manufacturing techniques to boost efficiency without compromising on durability, making our hanger bolts a reliable choice for projects that demand longevity and performance in challenging conditions.

Beyond technical prowess, we pride ourselves on building strong partnerships through responsive customer service and flexible logistics. Whether you need standard sizes or tailored designs, our production in China delivers timely, cost-effective results that help streamline your supply chain. Experience the difference with hanger bolts crafted to uphold your brand's reputation and meet the highest global standards.

Why Our Factory Stands Out for Superior Fastener Quality

At our facility, we don't just manufacture fasteners; we engineer reliability into every bolt, screw, and nut. What truly sets us apart is a relentless commitment to precision that starts long before production begins—our design team collaborates closely with clients to tailor solutions that withstand extreme stresses and environments, ensuring each component performs flawlessly under pressure. This collaborative approach means we're not just making parts; we're building partnerships that drive innovation and durability in industries ranging from aerospace to heavy machinery.

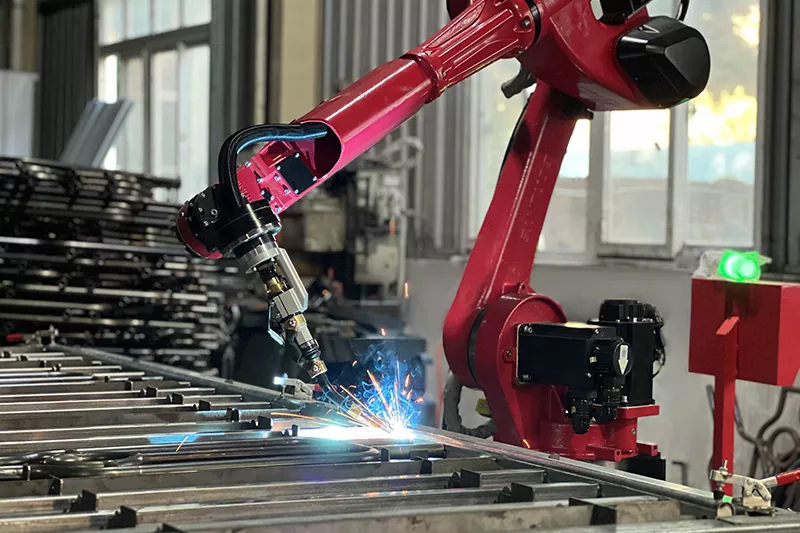

Beyond design, our manufacturing process integrates advanced robotics with skilled craftsmanship, allowing us to maintain micron-level tolerances consistently. We've invested in state-of-the-art quality control systems that perform real-time inspections during production, catching defects that others might miss. This proactive monitoring, combined with rigorous material testing—from tensile strength to corrosion resistance—guarantees that every batch meets or exceeds international standards, giving our clients confidence in the longevity and safety of their assemblies.

Ultimately, our edge lies in a culture of continuous improvement, where feedback from the field directly informs process refinements. By staying agile and embracing cutting-edge technologies like additive manufacturing for custom prototypes, we adapt quickly to evolving industry demands. It's this blend of human expertise, technological investment, and customer-focused flexibility that makes our fasteners not just products, but pillars of trust in critical applications worldwide.

Innovative Manufacturing Techniques for Reliable Bolts

Bolts are essential in countless applications, from automotive assembly to aerospace engineering, where reliability can make or break a project. To meet the increasing demands for durability and precision, manufacturers have turned to innovative techniques that go beyond traditional methods. Cold forging, for instance, compresses metal at room temperature to create bolts with superior grain structure and strength. This process reduces waste and enhances fatigue resistance, making bolts less prone to failure under stress. By adopting such advanced approaches, companies are producing bolts that not only meet stringent industry standards but also exceed expectations in harsh environments.

Another pivotal innovation is the use of additive manufacturing, or 3D printing, which allows for custom bolt designs with complex geometries that were previously impossible to achieve. This technique enables rapid prototyping and on-demand production, reducing lead times and costs. For example, bolts with internal cooling channels or lightweight structures can be fabricated to optimize performance in specific applications like electric vehicles or renewable energy systems. By integrating additive manufacturing, the industry is moving towards more flexible and sustainable production models that cater to niche markets and evolving technological needs.

Quality control has also seen a revolution with the integration of artificial intelligence and real-time monitoring systems. Sensors embedded in manufacturing equipment collect data on parameters such as torque, temperature, and material composition, allowing for immediate adjustments during production. This ensures each bolt meets exact specifications, minimizing defects and enhancing consistency. As a result, manufacturers can deliver bolts with unmatched reliability, backed by detailed traceability records. These innovations not only boost safety and efficiency but also foster trust among users who depend on bolts for critical operations.

Custom Solutions Tailored to Your Specific Needs

Forget one-size-fits-all approaches—our team takes the time to understand your unique challenges and goals, crafting solutions that fit like a glove. By diving deep into your specific context, we ensure every recommendation is practical and actionable, not just a generic fix.

We blend industry insights with a fresh perspective, avoiding cookie-cutter strategies to deliver innovations that truly resonate. Whether it's a bespoke software tool or a tailored process overhaul, our focus stays on what moves the needle for you.

The result? You get a solution that feels custom-made, saving time and resources while driving meaningful impact. Let's build something unique together—because your needs deserve nothing less.

Sustainability and Durability in Every Fastener We Craft

At our core, we believe that crafting fasteners isn't just about holding things together—it's about building a legacy. Sustainability isn't an add-on; it's woven into every step of our process, from sourcing recycled materials to ensuring each piece withstands the test of time. We've seen too many shortcuts lead to waste, so we focus on durability that reduces replacements and keeps resources in use longer.

What sets our approach apart is a blend of innovation and tradition. We use advanced alloys and coatings that resist corrosion and wear, but we also draw on decades of hands-on experience to refine designs for real-world stresses. It's not just about meeting specs—it's about creating fasteners that handle surprises, whether in harsh environments or everyday applications, making them reliable partners for projects big and small.

Beyond the product, we're committed to a lifecycle mindset. Our fasteners are engineered for easy disassembly and recycling at end-of-use, supporting circular economy principles. By prioritizing longevity and responsible sourcing, we help our customers build with confidence, knowing each fastener contributes to a more sustainable future without compromising on strength or performance.

Partner with Us for Unmatched Service and Global Reach

Imagine having a partner who not only understands your business goals but also anticipates your needs before they arise. We pride ourselves on delivering service that goes beyond expectations, built on a foundation of deep industry expertise and a genuine commitment to your success. Whether you're expanding into new markets or refining operations, our team is dedicated to providing tailored solutions that drive real results, ensuring you're always steps ahead.

Our global reach isn't just about having offices in key cities—it's about cultivating local insights and relationships that give you a competitive edge. We navigate cultural nuances and regulatory landscapes seamlessly, allowing you to focus on growth while we handle the complexities. With a presence spanning multiple continents, we offer a truly connected experience, enabling smooth collaboration and access to diverse talent pools that fuel innovation.

Together, we can create a partnership that transcends transactions, turning opportunities into sustainable achievements. Let's build something remarkable, backed by unmatched support and a worldwide network ready to propel your vision forward.

FAQ

The best factories combine advanced technology with stringent quality checks, ensuring every bolt meets precise specifications for durability and performance in demanding applications.

Rigorous testing, from material selection to final inspection, minimizes defects and ensures consistent strength, crucial for safety in construction and machinery.

Yes, they often offer bespoke solutions, tailoring dimensions, coatings, and materials like stainless steel to meet unique client needs in various industries.

Many adopt eco-friendly practices, such as using recyclable materials and reducing waste, aligning with global sustainability standards without compromising quality.

By investing in automation and R&D, factories produce bolts faster and more efficiently, often leading to cost savings and improved product longevity for end-users.

Reliable logistics and supply chain management prevent project delays, ensuring clients receive orders as scheduled to maintain operational continuity.

Look for certifications, customer reviews, and after-sales support, as these indicate long-term reliability and commitment to service excellence.

They regularly audit their processes and products against global benchmarks, like ISO, to guarantee compliance and build trust in export markets.

Conclusion

As the premier hanger bolt factory in China, we pride ourselves on setting the standard for quality fasteners that meet the demands of global industries. Our excellence in production is rooted in innovative manufacturing techniques, ensuring every bolt we craft is reliable and durable, backed by sustainable practices for long-lasting performance. By tailoring custom solutions to your specific needs, we go beyond one-size-fits-all approaches, offering precision and flexibility that distinguishes us in the market. From superior materials to advanced processes, our commitment to quality shines through, making us the trusted choice for partners worldwide.

Our factory stands out not just for product quality, but for unparalleled service and a global reach that supports seamless collaboration. We emphasize sustainability and durability in every fastener, reducing environmental impact while enhancing longevity. Partnering with us means gaining access to expertise and a responsive team dedicated to your success, driving innovation and reliability in fastening solutions. With a focus on customer-centric approaches and continuous improvement, we deliver unmatched value, solidifying our position as China's leading manufacturer. Choose us for fasteners that combine craftsmanship, customizability, and a commitment to excellence in every detail.

Contact Us

Contact Person: Nancy

Email: [email protected]

Tel/WhatsApp: +86-13365923720

Website: https://www.topfencesolar.com/