Characteristics of steel wire rope slings

2023-10-16

Steel wire rope slings are a type of lifting sling made from multiple strands of steel wire rope that are braided or twisted together to form a strong and flexible lifting device. These slings are commonly used in various industries, such as construction, manufacturing, shipping, and mining, for lifting and hoisting heavy loads.

Here are some key features and characteristics of steel wire rope slings:

1. Construction: Steel wire rope slings are typically made from multiple strands of high-strength steel wire ropes twisted or braided together. The wire ropes consist of individual steel wires twisted around a central core, forming a strong and durable structure.

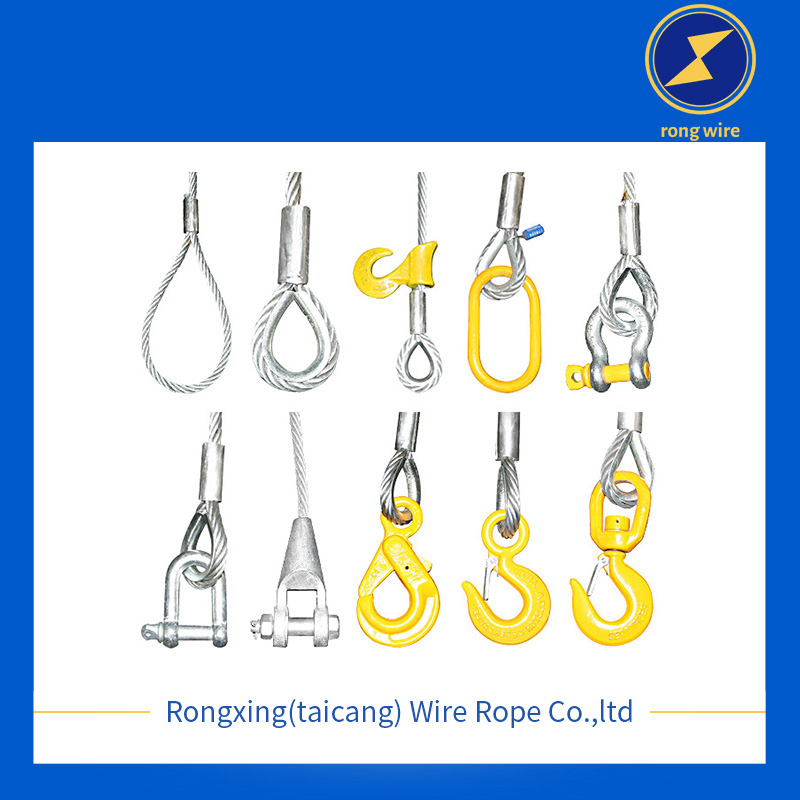

2. Strength and Load Capacity: Steel wire rope slings are designed to handle heavy loads and provide high tensile strength. The load capacity of a steel wire rope sling depends on factors such as the diameter and construction of the wire rope, the number of legs in the sling, and the type of fittings or attachments used.

3. Flexibility: Steel wire rope slings offer flexibility and maneuverability, allowing for easy attachment and positioning of loads. The flexibility of the wire rope enables the sling to conform to the shape of the load, providing a secure and balanced lifting solution.

4. Durability and Resistance: Steel wire rope slings are known for their durability and resistance to wear, abrasion, corrosion, and heat. They are suitable for use in harsh and demanding environments, including outdoor or marine applications.

5. Types of Configurations: Steel wire rope slings come in various configurations to suit different lifting requirements. Common types include single-leg slings, multi-leg slings (such as two-legged, three-legged, or four-legged slings), and endless or grommet slings. The configuration and arrangement of the legs depend on the lifting application and load characteristics.

6. Safety and Inspection: Safety is crucial when using steel wire rope slings. It is essential to follow industry safety guidelines, including proper rigging practices, load capacity limits, and regular inspection of the slings for signs of wear, damage, or deformation. Inspections should be carried out by trained personnel to ensure the integrity and reliability of the slings.

It's important to note that steel wire rope slings should be used in accordance with applicable regulations, standards, and manufacturer recommendations. Proper handling, storage, and maintenance are necessary to ensure the longevity and safe operation of the slings.

When selecting steel wire rope slings, factors such as the load capacity, working length, type of fittings, and environmental conditions should be considered. Consulting with lifting equipment specialists or rigging professionals can help determine the most suitable steel wire rope sling for specific lifting tasks.