A Comprehensive Guide to CNC Machining Parts: Revolutionizing Modern Manufacturing

2025-01-14

In the rapidly evolving landscape of manufacturing, CNC (Computer Numerical Control) machining has emerged as a cornerstone technology. By integrating precision, efficiency, and automation, CNC machining is transforming the way parts are designed and fabricated. In this blog, we’ll explore the intricacies of CNC machining parts, their applications, benefits, and why they are crucial in today’s industrial ecosystem.

What Are CNC Machining Parts?

CNC machining parts are components fabricated using CNC machines. These machines follow pre-programmed software instructions to cut, shape, and form materials into highly precise and complex designs. Common materials used include metals (aluminum, steel, titanium), plastics, composites, and even ceramics.

Key Processes in CNC Machining

1. Milling

Involves using rotating cutting tools to remove material and create intricate shapes. Ideal for parts requiring precision contours.

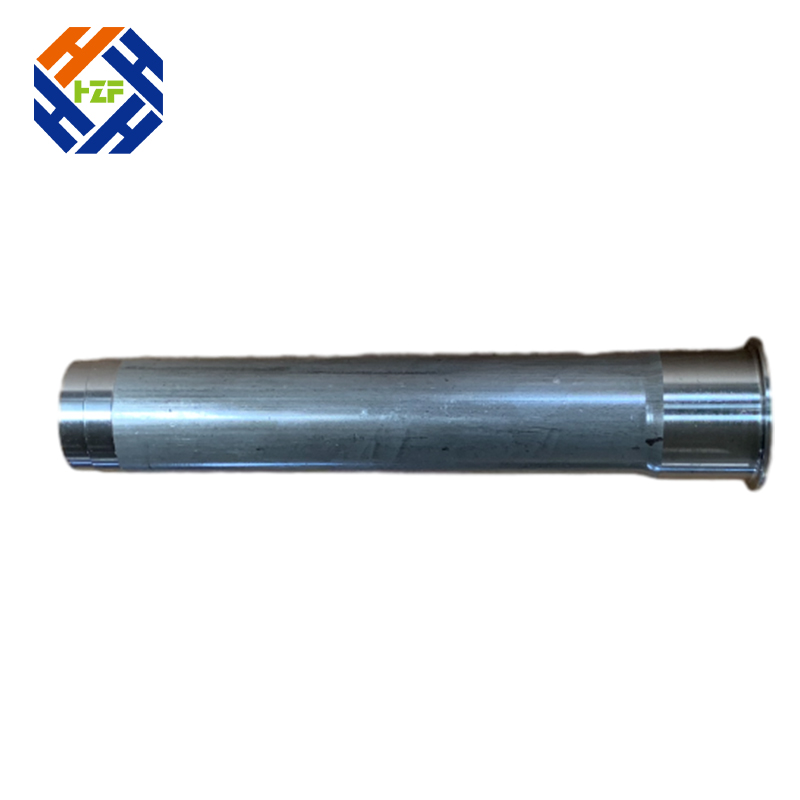

2. Turning

Utilizes a lathe to rotate the material while a cutting tool shapes it. This is perfect for cylindrical parts like shafts and bushings.

3. Drilling

Creates holes with extreme precision, often a precursor to threading or fastening.

4. Grinding

Ensures smooth surfaces and tight tolerances for finished parts.

5. Electrical Discharge Machining (EDM)

Uses electrical discharges to shape materials that are difficult to machine conventionally.

Applications of CNC Machining Parts

CNC machining parts are omnipresent across diverse industries due to their adaptability and precision:

1. Aerospace

Aircraft components demand exceptional precision and durability, achieved through CNC machining.

2. Automotive

Used for engine components, gears, and prototypes, ensuring safety and performance standards.

3. Medical

Surgical instruments, implants, and diagnostic equipment often rely on CNC-machined parts for their intricate designs.

4. Electronics

Enclosures, heat sinks, and connectors benefit from CNC’s ability to handle small and complex details.

5. Industrial Machinery

Custom tools, fixtures, and machine parts are fabricated for heavy-duty applications.

Benefits of CNC Machining Parts

1. Unparalleled Precision

CNC machining ensures tight tolerances, often down to microns, critical for high-performance parts.

2. Efficiency

Automation allows for faster production with minimal human intervention.

3. Versatility

CNC machines can produce a wide range of parts from different materials, catering to varied industries.

4. Scalability

From one-off prototypes to large-scale production runs, CNC machining adapts seamlessly.

5. Cost-Effectiveness

Despite the initial investment, CNC machining reduces material waste and labor costs in the long term.

Design Considerations for CNC Machining Parts

When designing parts for CNC machining, several factors can optimize the process:

- Material Selection: Choose materials suited to your part’s functionality and machinability.

- Tolerance Specifications: Avoid overly tight tolerances unless necessary, as they can increase machining time and costs.

- Tool Accessibility: Ensure features are accessible for standard tools to reduce complexity.

- Surface Finish: Specify finishing requirements for aesthetics and functionality.

Challenges and Solutions

Despite its advantages, CNC machining comes with challenges:

- High Initial Cost: Investment in CNC machines and programming expertise is substantial, but long-term savings outweigh initial expenses.

- Material Limitations: While versatile, not all materials are easily machinable. Advanced techniques like EDM can address this limitation.

- Skill Requirements: Experienced operators and programmers are essential to maximize CNC capabilities.

The Future of CNC Machining Parts

The rise of technologies like AI-driven programming, 5-axis machining, and additive manufacturing integration are enhancing the capabilities of CNC machining. These advancements promise even greater precision, efficiency, and flexibility in producing complex parts.

Conclusion

CNC machining parts are pivotal to modern manufacturing, delivering precision, speed, and versatility. As industries continue to demand higher performance and tighter tolerances, CNC machining stands out as a critical technology. Whether you’re in aerospace, automotive, or medical fields, investing in CNC machining parts ensures superior quality and innovation for years to come.

Are you exploring CNC machining solutions for your business? Feel free to connect with us for expert guidance and tailored solutions to meet your unique manufacturing needs!